EcoRubCool - Elastocaloric materials based on waste rubber for an efficient cooling. MKT2025/0195_E

EcoRubCool project aims to address this gap by developing a novel rubber material to produce an eC effect viable for an efficient heating/cooling/refrigeration technology. Our method involves the selection and processing of natural rubber-based materials, using renewable and recycled fillers which will specifically serve as enhancer of the eC effect, and to increase the thermal conductivity, mandatory to transfer the heat/cool from the materials surface to an external media. Ref. MKT2025/0195_E

EcoRubCool - Elastocaloric materials based on waste rubber for an efficient cooling. MKT2025/0195_E

EcoRubCool project aims to address this gap by developing a novel rubber material to produce an eC effect viable for an efficient heating/cooling/refrigeration technology. Our method involves the selection and processing of natural rubber-based materials, using renewable and recycled fillers which will specifically serve as enhancer of the eC effect, and to increase the thermal conductivity, mandatory to transfer the heat/cool from the materials surface to an external media. Ref: MKT2025/0195_E

El repte/The challenge

Cooling and refrigeration are important engineering achievements of the 20th century and are essential for daily life, from preserving food and drugs to cooling data centres and buildings. However, the demand for cooling is expected to triple by 2050, increasing energy consumption and greenhouse gas emissions. Currently, most of the Heating, Ventilating and Air Conditioning – refrigeration systems are based on Vapor compression cycles (VCC), where non-ecological refrigerants such as chlorofluorocarbons and hydrofluorocarbons are used, with a high Global Warming Potential, causing 3% of global greenhouse emissions. While solid-state cooling prototypes based on magnetocaloric and electrocaloric effects have been developed, they

face challenges. Magnetocaloric materials require expensive high magnetic fields and contain rare-earth elements. Electrocaloric materials require high electric fields and exhibit fatigue damage. Elastocaloric materials show to be promising candidates for their giant caloric effect, but the mechanical stresses required limit their commercial applicability.

La tecnologia/The technology

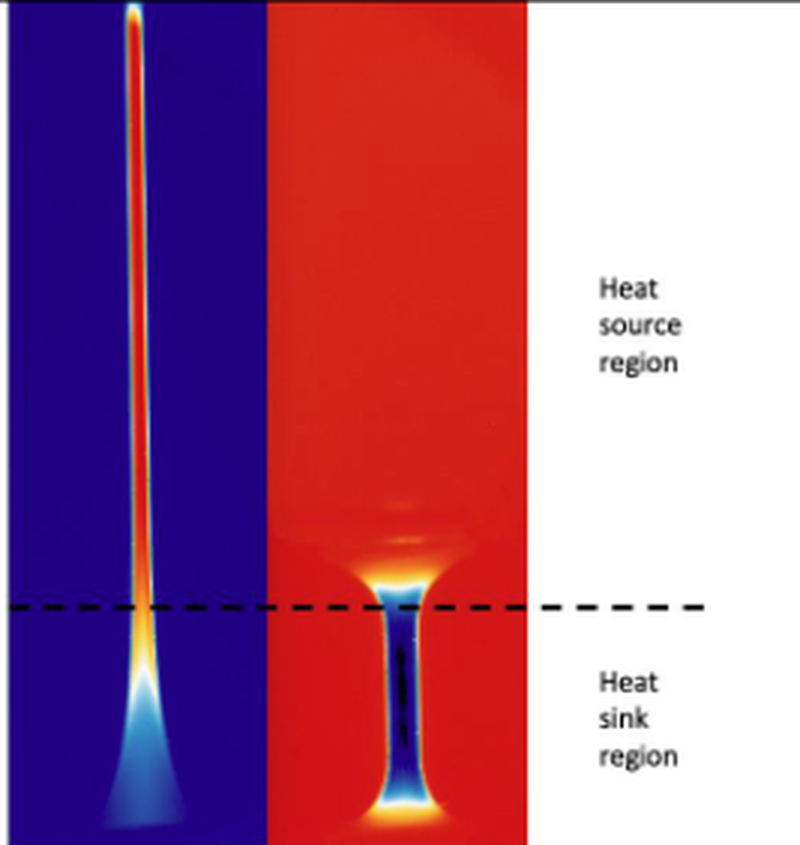

Our preliminary lab-test results indicate that releasing up to 3 MPa of mechanical stress produces heating/cooling with

temperature span of around 20°C. However, the question of heat/cool transport from the rubber to an external media is

a challenge as the loss of temperature is huge: a cooling of 10ºC in the rubber can only induce a cooling of a circulating

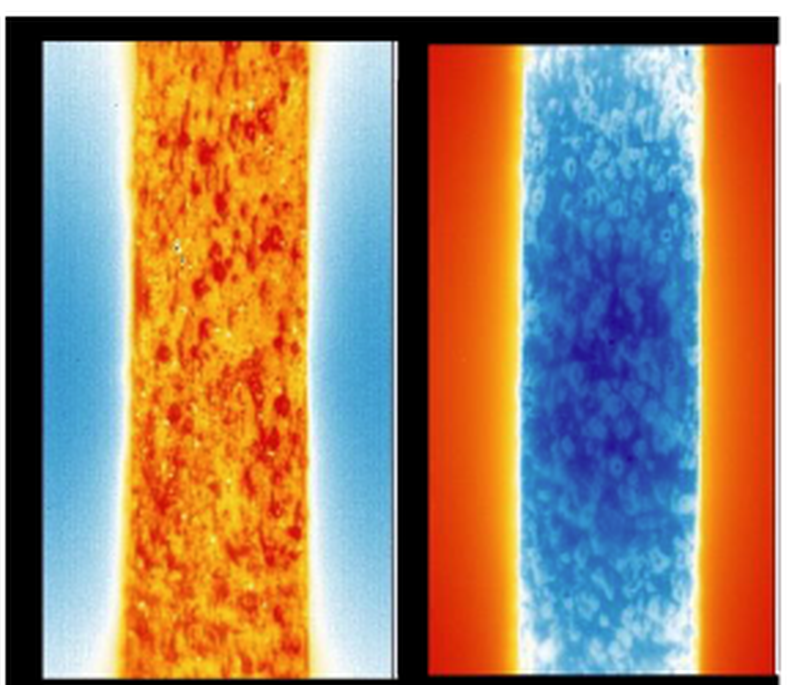

fluid of 3ºC at this moment. NR-based materials with renewable/recycled fillers, such as waste latex or waste fillers have been elaborated. We demonstrated by in-situ X-rays that the presence of waste fillers promotes the eC effect by generating heterogeneous temperature field. Our objective is to achieve a composition and geometry of the rubber product enabling heating, cooling and refrigerating. The materials components (matrix, waste fillers, natural fibres) are chosen with a targeted increase of +30% of heating and cooling capacity, concomitantly with an increase of 300% of the thermal conductivity and a

multiplication by 10 of the electrical conductivity, as compared to the pristine natural rubber.

Avantatges innovadores/Innovative advantages

The proposed technology shows economical, societal and environmental advantages. It would contribute to the cooling

market that has a huge potential for growth, especially for households, due to global warming and modern building

architecture with larger glazing areas. We have designed products based on natural rubber containing waste particles as enhancer of the elastocaloric effect. These preliminary results have been published in N Candau et al. Elastocaloric effect in vulcanized natural rubber and natural/wastes rubber blends. Polymer 236, 124309 2021.

The presence of waste rubber and cellulose nanocrystals as fillers into an NR matrix have shown a synergistic effect on its elastocaloric (eC) effect. These compositions show a higher potential for heating/cooling applications as compared to the material used for the publication (see paragraph above). For this reason, they are in the process of protection through a patent published with number EP4286471, a positive report was received from the European Patent Office (EPO).

Fase actual de desenvolupament/Current stage of development

A challenge is the compatibility between the rubber and fillers, so we are working on treating the waste rubber particles by a physical devulcanization process. We prepare composites comprising natural and treated waste rubber, and recycled carbon black, to then improve the eC effect. In particular the rCC are intended to increase the level of heating/cooling and to accelerate the thermal transfer with the environment. TRL4 – 5.

Aplicacions i mercat objectiu/Applications and target market

The target markets are the Heating, Ventilation, Air Conditioning, and Refrigeration (HVAC-R) market and the Heating & Cooling, Heat Pump, and Thermal Management System Markets. We are currently conducting a go to market strategy analysis with an external consultant to help us definint a roadmap.

NR specimen temperature during loading (left) and unloading (right).

Temperature field in NR/GTR specimen (bottom) during heating (left) and cooling (right). Images width = 2 mm.

Oportunitats de negoci/Business opportunity

Cerca de col·laboradors per avançar en el desenvolupament i implementació a mercat/Looking for collaborators to advance in the development and market implementation

Estat de la propietat intel·lectual i industrial/Intelectual property status

PCT sol·licitada/PCT application

Contacte/Contact

Servei de Gestió de la Innovació

T. +34 934 13 76 23

gestio.innovacio@upc.edu