Mixture of cement with recycled material for the formation of concrete, and preparation procedure. MKT2025/0184_C

It is an invention for the construction and architecture sector, which presents a new production of pieces with recycled and/or highly porous material intended for building façades, roofs, and pavements. This invention defines: i) a new cement mixture composed from the reuse of industrial waste and porous materials, allowing translucency and bioreceptivity; ii) the innovative procedure for manufacturing the pieces. Ref. MKT2025/0184_C

Mixture of cement with recycled material for the formation of concrete, and preparation procedure. MKT2025/0184_C

It is an invention for the construction and architecture sector, which presents a new production of pieces with recycled and/or highly porous material intended for building façades, roofs, and pavements. This invention defines: i) a new cement mixture composed from the reuse of industrial waste and porous materials, allowing translucency and bioreceptivity; ii) the innovative procedure for manufacturing the pieces. Ref: MKT2025/0184_C

El repte/The challenge

The environmental impact of construction is among the highest, with approximately 40% of global carbon emissions attributed to buildings and infrastructure. To meet the goal of reducing this impact, as outlined by European policies promoting an ecological transition—such as the European Green Deal, which aims for carbon neutrality by 2050—it is essential to consider not only the energy consumed by a building during its operational life but also the energy used in its construction and demolition. In this context, facades play a crucial role in building energy efficiency. There is a need for new construction solutions that encourage the use of recycled and/or recyclable materials and modular systems, while taking embodied energy into account.

La tecnologia/The technology

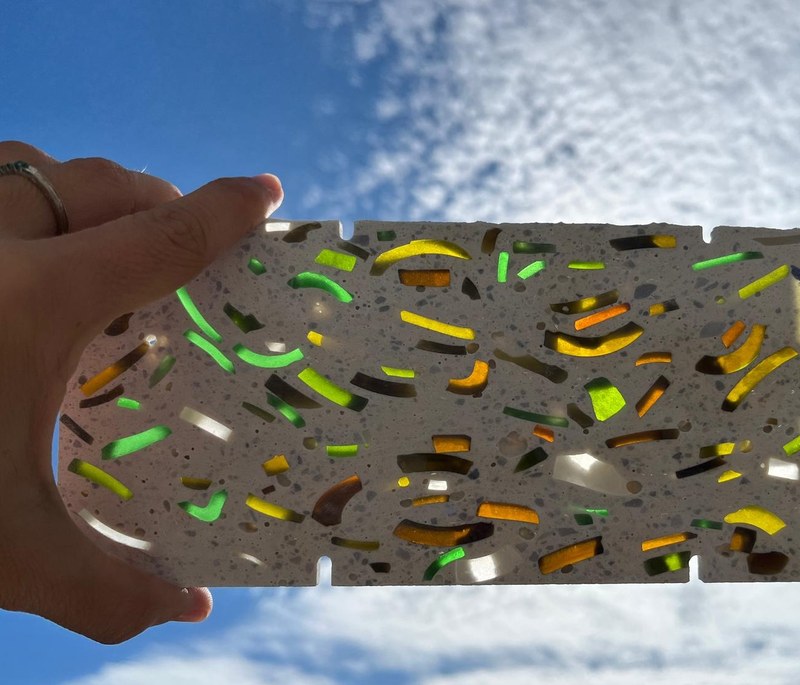

The proposed technology presents a new material and a different production system. The material is a concrete with a high percentage of recycled material, incorporating the aggregate (RCD), the waste from glass recycling (CSP (ceramic stone porcelain)), the recycled cellular glass, and recycled glass fibers, among others. And porous, with the incorporation of Super Absorbent Polymers (SAP) and/or recycled Silica gel. The manufacturing applies the cutting technique after the hardening of the concrete. The result is small pieces of lightweight, resistant, and porous concrete with recycled materials for lattices as solar filters, based on the research carried out within the framework of the project “Intelligent solar control devices for the rehabilitation of envelopes from waste” of “Ecological Transition and Digital Transition Projects” of the Ministry of Science TED2021-130155B-I00, funded by MCIN/AEI/10.13039/501100011033 and by the European Union “NextGenerationEU”/PRTR.

Avantatges innovadores/Innovative advantages

It is an innovative material because it is: 1) concrete with a high percentage of recycled material, >50% by weight; 2) lightweight, allowing for the construction of, for example, façades of 40–100 kg/m²; 3) with a pH lower than 8.5, suitable for biological colonization; 4) porous, allowing an increase in the evaporative cooling effect; and 5) highly resistant, for applications where impacts occur.

The production by cutting allows: 1) achieving finishes where the pores emerge on the surface, enabling bioreceptivity, moisture retention, and evaporative cooling; 2) new and suggestive surface finishes, since the internal materials of the concrete matrix are exposed to the exterior; and 3) the creation of specific joints to connect it with substructures.

From this material and production process, small pieces are obtained for lightweight and resistant solutions for façades and roofs, which adapt to the current comfort needs of obsolete buildings with old structures that require renewing their envelopes with innovative lightweight solutions.

Fase actual de desenvolupament/Current stage of development

The patent is in an advanced stage: the cement mixture has been formulated, the pieces have been manufactured optimizing the cutting process, and they have been installed on a façade as a uniform lattice. Thermal, lighting, and environmental quality tests have been carried out. The bioreceptivity tests remain to be completed in order to finalize the comprehensive evaluation of the system.

Aplicacions i mercat objectiu/Applications and target market

For the construction and architecture sector, specifically for façades, roofs, and pavements where translucency, impact resistance, lightness, and/or circularity are required. For example, in envelopes that need translucency to allow the passage of light. On the other hand, in buildings located in public spaces or sports areas where impacts make the use of ceramic solutions difficult. Also, in the rehabilitation of buildings that require lightweight and circular material solutions.

Image of one of the possible cutting processes and some examples of possible resulting pieces.

Image of one of the possible finishing results.

Oportunitats de negoci/Business opportunity

Cerca de col·laboradors per avançar en el desenvolupament i implementació a mercat/Looking for collaborators to advance in the development and market implementation

Estat de la propietat intel·lectual i industrial/Intelectual property status

Patent sol·licitada/Applied patent

Contacte/Contact

Servei de Gestió de la Innovació

T. +34 934 13 76 23

gestio.innovacio@upc.edu